VINOD RICE PARBOILING SYSTEMS

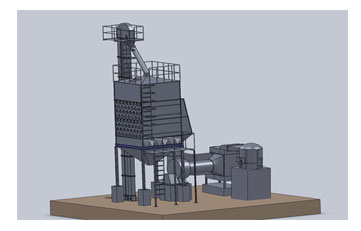

Latest knowledge of parboiling complete plant equipment for Worldwide experience techniques

- Batch system, Open Tank without Pressure

- Batch system, Open Tank Pressure

- Continuous pressure cooking system in vertical cooker Brown rice parboiling

- Laboratory parboiling system for research and test run

Advanced Techniques of Parboiling Systems

Parboiled rice is one of the most popular rice products in Indian and becomes more important not only by the fact of improved nutritional value but also by the improved cooking and processing properties which are desired from the industrial point of view.

Apart from the nutritional importance of parboiled rice there are plenty of advantages and effects which makes parboiling attractive. Those advantages are for instance the increased head rice yield during milling of parboiled rice, the reduced stickiness of the cooked rice and the improved cooking behavior of the parboiled rice.

There are presently a lot of traditional and industrial methods where the basic steps like soaking, thermal treatment (steaming or cooking) and drying often only differ by the application of different techniques and process parameters. In rice cultivation countries generally paddy (raw rice) is used for parboiling, in Indian there is a progressive to parboil also brown rice.

Apart from a constant quality the rice industry requires special quality specification of the rice products. A necessary prerequisite for this is the knowledge of the certain impacts of process parameters to different rice varieties and quality aspects on the final product. To achieve this special aim modern parboiling equipment is needed which permit to select adequate process parameters according to individual customers requirements.

Leading technology for all parboiling aspects can be provided by VINOD parboiling techniques. Batch system, open tank without pressure, continuous pressure cooking systems and recently brown rice parboiling indicate the wide range of VINOD Parboiling possibilities. VINOD Rice Parboiling technologies are based on many experiences from plants around the world and on intensive research and development at the own Parboiling Test facilities.

General Impacts of Conventional Parboiling

- Increased head rice yield during milling

- Simplified hulling process

- Uniform and stabil cooking and processing properties

- Reduced stickiness of cooked and processing properties

- Reduced stickness of cooked rice

- Improved nutritional value and extended shelf life

Impacts of Brown Rice Parboiling

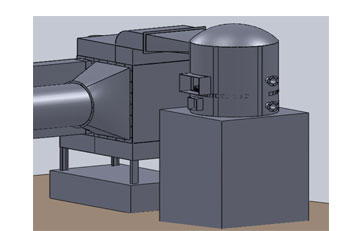

HEAT EXCHANGER

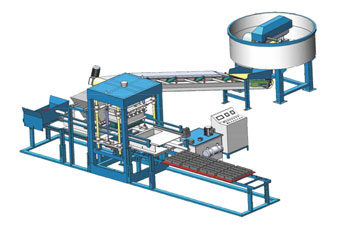

Hydraulic Operated Concrete Block Making Machine

HYDRAULIC CONCRETE MIXER-10/7 cft powered by 6.5 HP Diesel Engine

CONCRETE MIXER 7/5 and 5/3 ½ Cu Ft.

Product